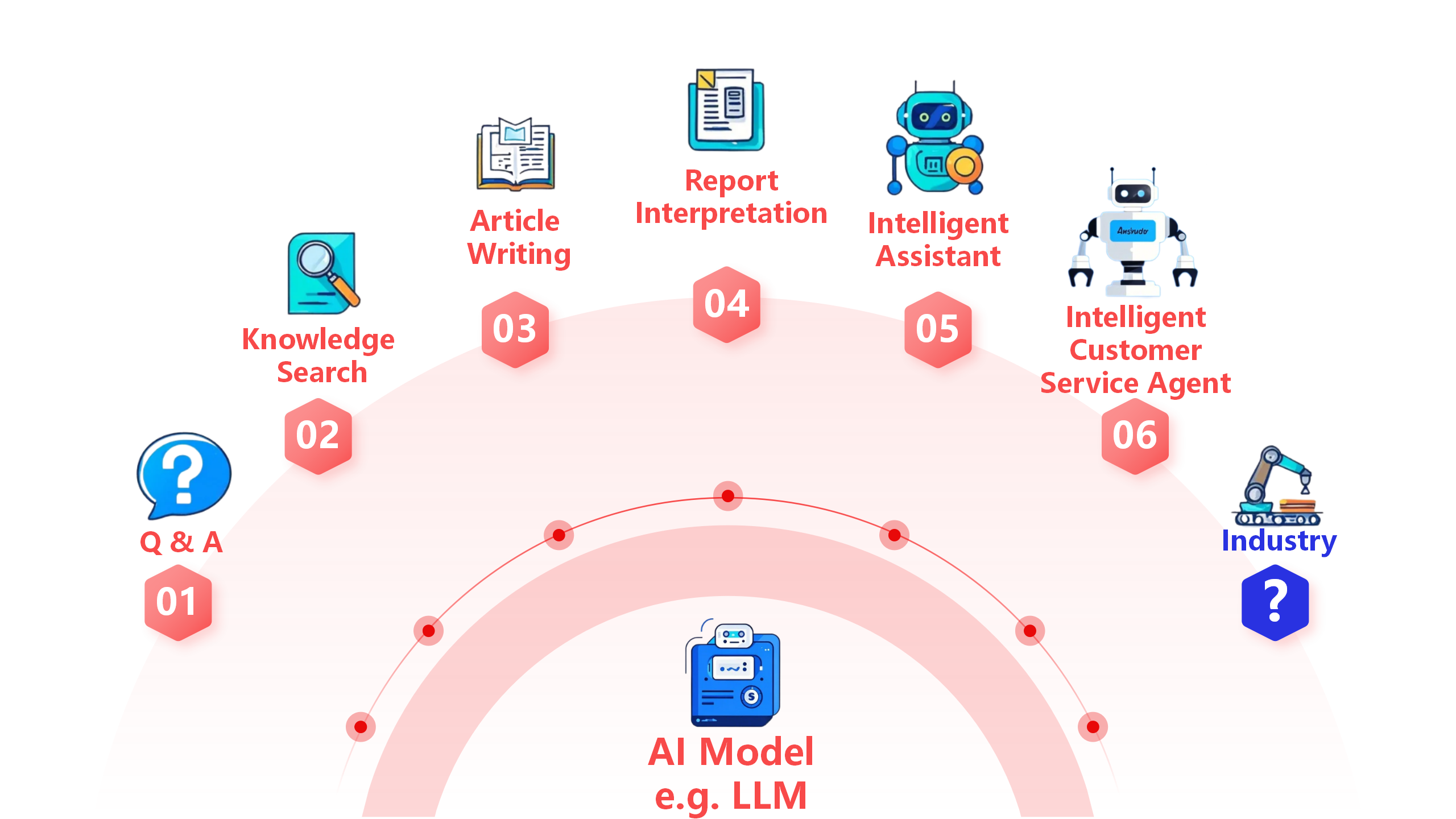

Ability to bridge the gap in large model calculations in specific industries

A Computing Tool with a Difference in the Age of AI

🤔 Current trends

AI shines in the content industry with its creativity and randomness, but it doesn't seem to be good enough in areas that require mathematical calculations, such as in industry.

The "black box" nature of AI models makes it difficult for us to understand the correspondence.

The stability and interpretability issues of AI models have caused some resistance to the application of AI models in real industry.

🏭 Focus on real industries | Mining

For mining, in daily ore sales, we often come across customers who will put forward specified requirements on the index of the required ore, while meeting the current company does not have the index of the ore.

Therefore, a special processing link, mix ore, will appear in the ore trade.

As shown in the figure below, the overall process of mixing ore includes 5 stages:

1️⃣Ore demand communication

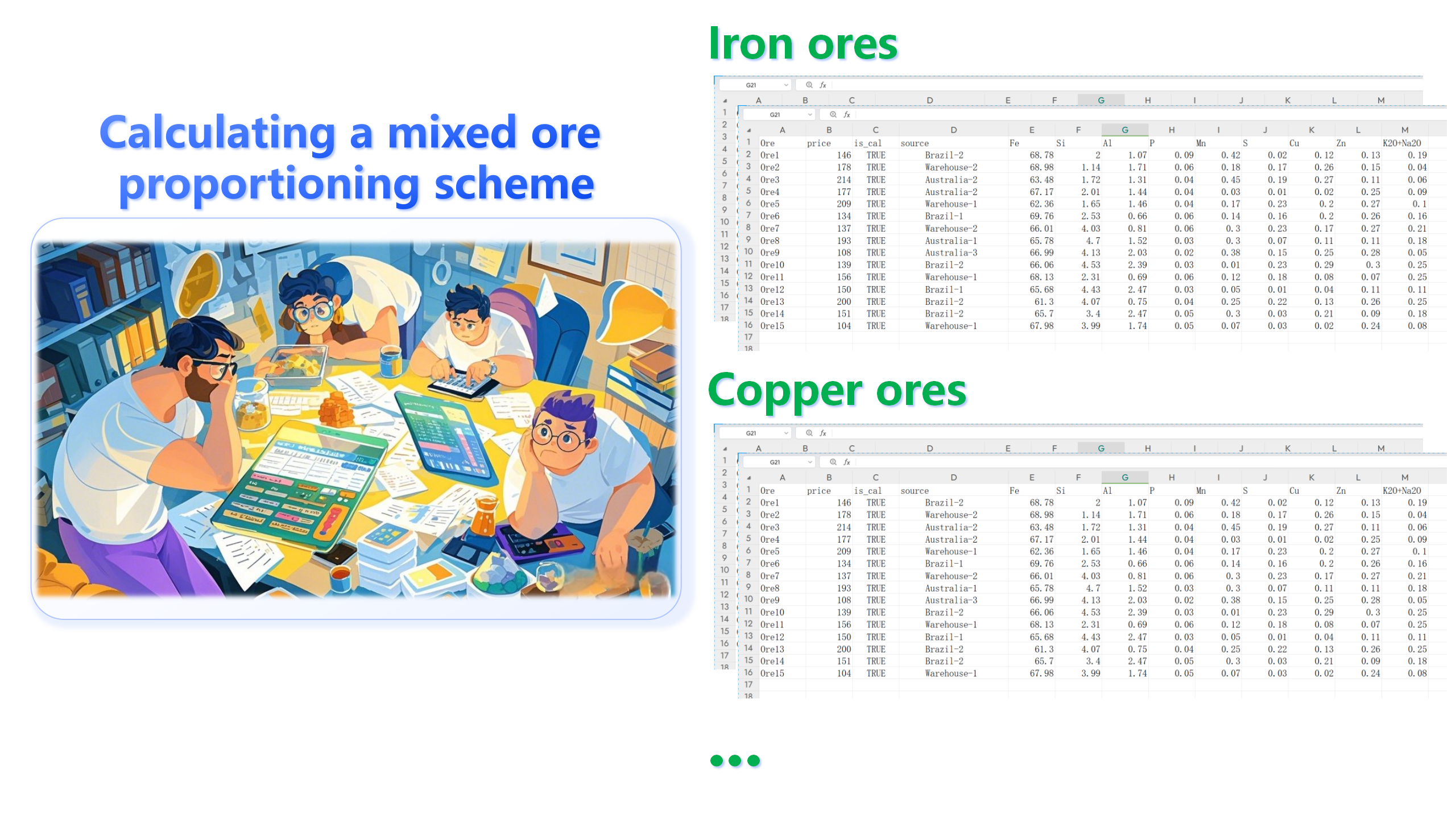

2️⃣Calculating a mixed ore proportioning scheme

3️⃣Purchase many ores

4️⃣Mix ore

5️⃣Mixed ore for purchase

The second step is the most important. This ore procurement plan directly affects the company's procurement cost each time, and thus affects the company's annual profit.

📝 Current calculation method | Manual calculation

Mineral purchasers need to meet specific customer requirements for mineral composition and quantity.

In the case of huge demand, manual calculation is not only time-consuming and labor-intensive, but also difficult to ensure the lowest cost.

However, relying on large models (LLM) makes it difficult for us to fully trust the accuracy of their mathematical calculations.

✅ 💻 New calculation method | MixOrePlan

Our tool is mainly used in the mining industry. There is an introduction to this tool on the homepage, including its functions, positioning, etc., which will not be repeated here.

All I need to do is enter the final mixed ore requirement and the data for each raw ore. The tool automatically calculates the minimum purchase cost.

The calculations were so fast that they were done in the time it took to take a sip of water. This tool has saved your a lot of money by giving you a more cost-effective solution for mixing minerals than the one I spent hours figuring out.

Considering that we purchase 1 million tons of ore per year, this means that our cost savings grow gradually over the year, saving roughly $3 million to $5 million a year.

This tool is undoubtedly a distinctive innovation in the era of big models. For industrial practitioners and mining companies, these tools may be what we really need.